ProductsCenter

Cangzhougold seal packagingMachinery Co., Ltd.

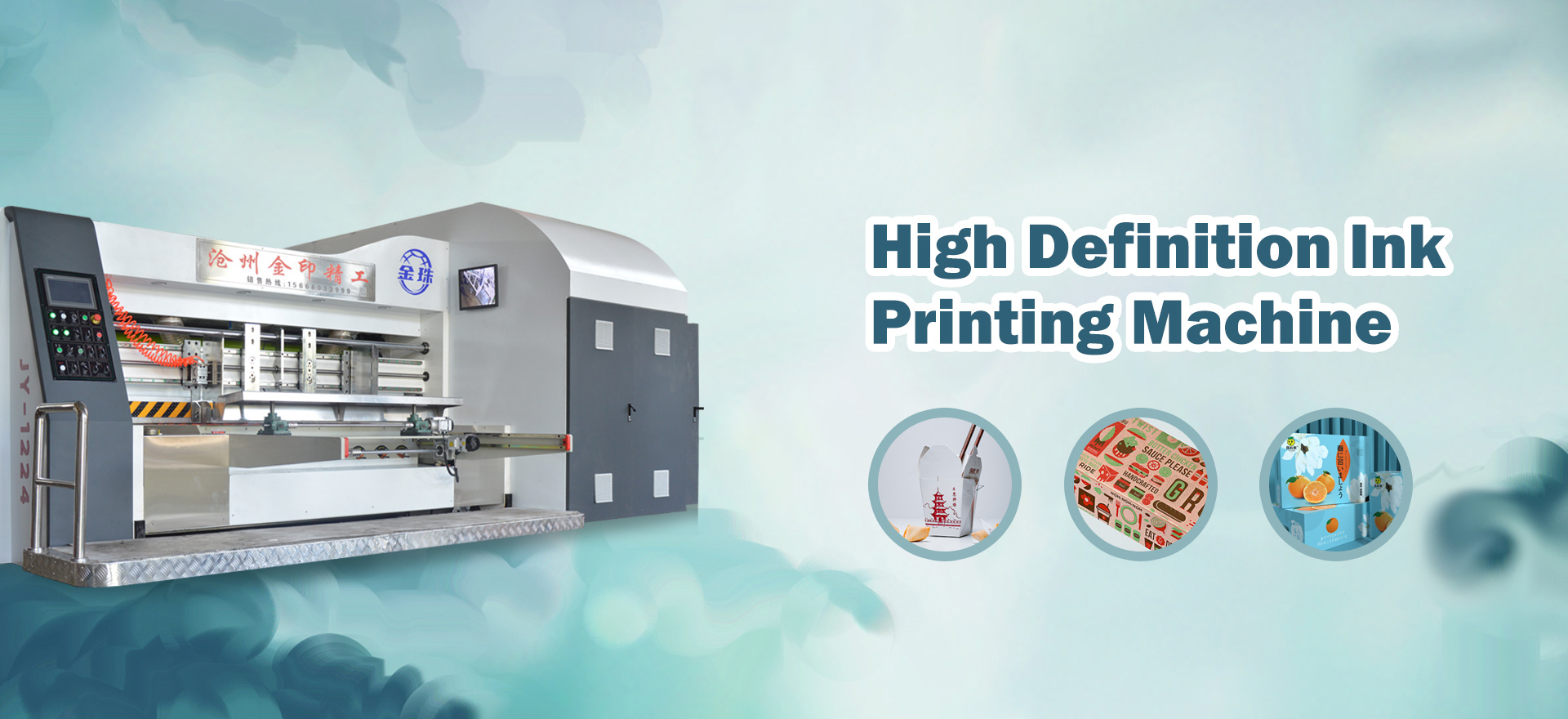

Specializing in ink printing slotting machine series and a full set of carton equipment manufacturers

· 30 years of industry experience

The company's assets exceed 100 million.

More than 50 skilled workers

More than 800 customers have been served.

cangzhou jinyin packaging machinery co., ltd. is a production of ink printing die cutting machine, printing slotting machine, printing slotting die cutting machine, hd ink printing machine, high speed printing linkage line and other kinds of packaging and printing equipment professional company.

With complete mechanical processing equipment, professional production, rich manufacturing experience, strong technical strength, perfect testing process and strict management system, the company has become strong in the domestic packaging machinery industry. We adhere to the "quality of survival, science and technology and development" of the company concept, learn from the strengths, absorb the essence of domestic and foreign mechanical research, carefully design and production of each equipment, intentions to serve every friend.

Rich production experience

More than 30 years of industry experience

Products sold globally

Cooperation with more than 80 countries

Excellent quality is guaranteed

Get customers always praise

Obtain many honorary certificates

More than 10 related patents

Corporate Culture

Choose one thing, the whole life, not for the prosperity and ingenuity!

A one-stop management system of production-inspection-commissioning-sales-after-sales service has been established; each machine and each component is strictly controlled.

Perfect detection process, strict management system, become the leader in the domestic packaging machinery industry.

Complete mechanical processing equipment, professional production, rich manufacturing experience, strong technical strength.

Latest News